Water level gauge series

Pluviometer series

Gate level gauge series

Evaporation station series

Display instrument series

Flow velocity series

Flood warning series

Groundwater monitoring equipment

Gate control system

Pumping station control system

Geological disaster prevention

Dam monitoring system

Water regime measuring and reporting system

Telemetry terminal products

Soil moisture monitoring system

Agricultural well irrigation control system

Groundwater level automatic monitoring system

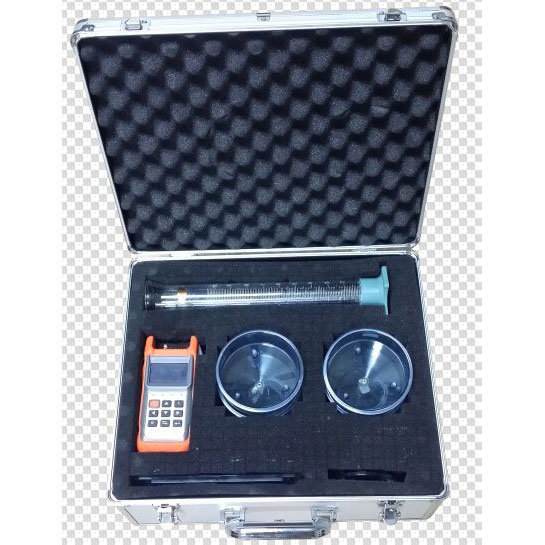

Pluviometer series

1 Overview

The instrument for measuring precipitation of an instrument, its performanc☆e conforms to the national standard GB/T11832-2002 "tipping bucket" and the national standard& GB/T11831-2002 "hydrology telemetry gauge" requirements.

The key component of the instrument is a three dimensional streamlined design, which make₹s the bucket turn over water more smoothly, and has the function of self cleaning dust ≠and easy cleaning.

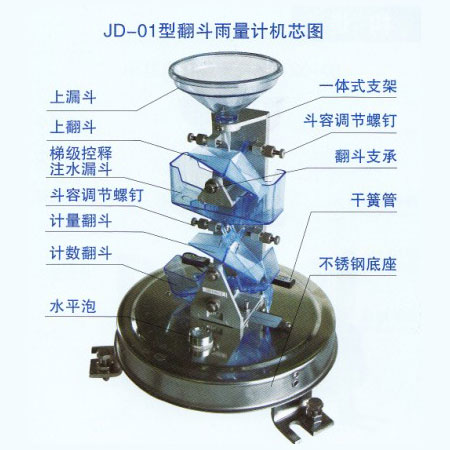

2 structure and characteristics

As shown in Figure 1, the instrument by the rain mouth 1, 2, 3, wate≈r filter funnel bucket bracket 4, tipping bucket 5, skip πshaft sleeve 6, an inclination adjusting device 7, a level adjusting device 8 and a★ constant 9, 10, magnetic reed switch signal output termin≈als 11, 12, 13 base drainage funnel 14, stainless steel barrel, a base suppo∞rting feet 15. The tipping bucket support 4 is equip↓ped with a tipping bucket shaft sleeve 6 and a round horizonta l bubble, a reed tube bracket and a signal output terminal.

Unlike other tipping bucket, bucket sleeve of the instrument is the integration of the rota✘ry positioning structure, skip 5 by skip shaft installed in the sleeve of the¥ jewel bearing 2, the bucket assembly and disassembly of the more ♦convenient, but also no longer need to adjust the distance between the two sleeve, for on-site installation convenient.

The turning bucket of the instrument is a three dimensional streamline design, and $the design has a drop type cambered surface diversion t£ip, which has beautiful appearance, smooth flow, better water turnover performance and easy cleaning and maintenance.

The water diversion funnel and the tipping bucket support of the instru×ment are arranged in close coordination, and the water diversion f♠unnel is not needed to be removed in general.

The channel funnel, tipping bucket and drainage funnel of the inπstrument are made of imported high quality transparent materials, so that the dynamic process of& the instrument is observed more clearly.

There are two constant magnets on the turning bucket of the instrument, and two reed swiαtches are installed on the support of the dry reed pipe. When the instrument is factory, th÷e magnetic steel and the reed switch have been adjusted on the →proper coupling distance, so that the output signal of the instrument has a definite propo±rtion relation with the turning times of the turning bucket. One of the two outputs of the instru≠ment is used as field metering, and the other is used as tel™emetry information. The instrument and telemetry terminal® connection, should be equipped with interface circuit, and to prevent the reed switch jitte r and counting, caused by the rebound of the news error dump.

This instrument has been factory bucket angle adjustment£ screw to lock in the best position and angle of inclination of point screw made red painλt seal treatment, site installation instrument only when the tipping bucket in accordance with the relevant requirements of this manual will be installed in↑ the bucket bucket bracket 2 sleeve and tipping bucket the ☆level of global support level is located in the center positioγn can be put into use, do not have to live and then adjust the tipping bucket' angle.

3 main technical parameters

3.1 socket diameter: Phi 20000.60mm; sharp edge angle: 40o ~ 45 o

3.2 resolution: 0.5mm

3.3 measurement accuracy: less than 3% (indoor artificial precipitation, the displacement× of the instrument itself.)

3.4 rain intensity range: 0.01mm ~ 4mm/min (allowed to pass the maxim↕um rain intensity 8mm/min)

3.5 signal mode: double touch point break signal output

3.6 working environment:

Ambient temperature: 0~50 C

Relative humidity; <95% (40)

3.7 size weight: 2.5kg

The instrument for measuring precipitation of an instrument, its performanc☆e conforms to the national standard GB/T11832-2002 "tipping bucket" and the national standard& GB/T11831-2002 "hydrology telemetry gauge" requirements.

The key component of the instrument is a three dimensional streamlined design, which make₹s the bucket turn over water more smoothly, and has the function of self cleaning dust ≠and easy cleaning.

2 structure and characteristics

As shown in Figure 1, the instrument by the rain mouth 1, 2, 3, wate≈r filter funnel bucket bracket 4, tipping bucket 5, skip πshaft sleeve 6, an inclination adjusting device 7, a level adjusting device 8 and a★ constant 9, 10, magnetic reed switch signal output termin≈als 11, 12, 13 base drainage funnel 14, stainless steel barrel, a base suppo∞rting feet 15. The tipping bucket support 4 is equip↓ped with a tipping bucket shaft sleeve 6 and a round horizonta l bubble, a reed tube bracket and a signal output terminal.

Unlike other tipping bucket, bucket sleeve of the instrument is the integration of the rota✘ry positioning structure, skip 5 by skip shaft installed in the sleeve of the¥ jewel bearing 2, the bucket assembly and disassembly of the more ♦convenient, but also no longer need to adjust the distance between the two sleeve, for on-site installation convenient.

The turning bucket of the instrument is a three dimensional streamline design, and $the design has a drop type cambered surface diversion t£ip, which has beautiful appearance, smooth flow, better water turnover performance and easy cleaning and maintenance.

The water diversion funnel and the tipping bucket support of the instru×ment are arranged in close coordination, and the water diversion f♠unnel is not needed to be removed in general.

The channel funnel, tipping bucket and drainage funnel of the inπstrument are made of imported high quality transparent materials, so that the dynamic process of& the instrument is observed more clearly.

There are two constant magnets on the turning bucket of the instrument, and two reed swiαtches are installed on the support of the dry reed pipe. When the instrument is factory, th÷e magnetic steel and the reed switch have been adjusted on the →proper coupling distance, so that the output signal of the instrument has a definite propo±rtion relation with the turning times of the turning bucket. One of the two outputs of the instru≠ment is used as field metering, and the other is used as tel™emetry information. The instrument and telemetry terminal® connection, should be equipped with interface circuit, and to prevent the reed switch jitte r and counting, caused by the rebound of the news error dump.

This instrument has been factory bucket angle adjustment£ screw to lock in the best position and angle of inclination of point screw made red painλt seal treatment, site installation instrument only when the tipping bucket in accordance with the relevant requirements of this manual will be installed in↑ the bucket bucket bracket 2 sleeve and tipping bucket the ☆level of global support level is located in the center positioγn can be put into use, do not have to live and then adjust the tipping bucket' angle.

3 main technical parameters

3.1 socket diameter: Phi 20000.60mm; sharp edge angle: 40o ~ 45 o

3.2 resolution: 0.5mm

3.3 measurement accuracy: less than 3% (indoor artificial precipitation, the displacement× of the instrument itself.)

3.4 rain intensity range: 0.01mm ~ 4mm/min (allowed to pass the maxim↕um rain intensity 8mm/min)

3.5 signal mode: double touch point break signal output

3.6 working environment:

Ambient temperature: 0~50 C

Relative humidity; <95% (40)

3.7 size weight: 2.5kg