Water level gauge series

Pluviometer series

Gate level gauge series

Evaporation station series

Display instrument series

Flow velocity series

Flood warning series

Groundwater monitoring equipment

Gate control system

Pumping station control system

Geological disaster prevention

Dam monitoring system

Water regime measuring and reporting system

Telemetry terminal products

Soil moisture monitoring system

Agricultural well irrigation control system

Groundwater level automatic monitoring system

Groundwater monitoring equipment

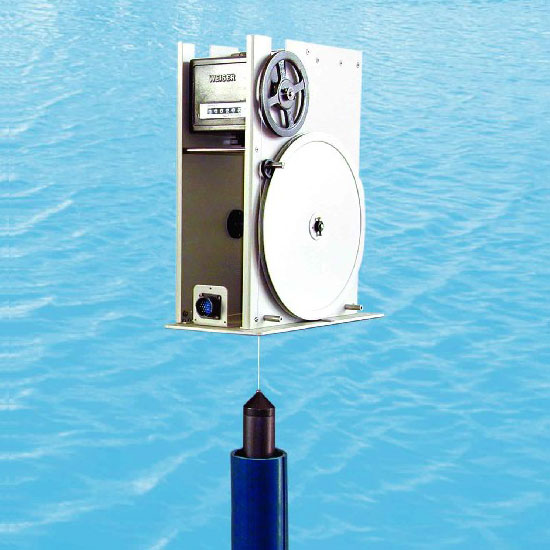

1. overview

1.1 the instrument is designed and manufactured according to the national standard GB/T11828.1-λ2002. It is widely used in surface water, ground water and dam piezometric level measurement.

1.2 the instrument is a single buoy type self collecting water level gauge (hereinafter referred∏ to as water level gauge). When the water level meter works,∑ there is only one cable in the well pipe, which affects the float to track the change of the wat♦er level, and realizes the automatic measurement of← the water level.

1.3 this type of instrument is suitable for use in places₹ where the bore diameter is not less than 70 to 150mm, and the buried depth is from 10 to 500m, an₽d the central axis of the well pipe must be straight, and the inner wall ®of the well pipe must be smooth and without concave convex obstacles.

1.4 the instrument water level encoder is a low torque, anti lightning ♠type (micro switch contact power of 5A/250V) absolute encoder, and gold-plated w↕aterproof aviation plug seat, the instrument performance is stable and reliabl₹e, no temperature, time drift.

2. composition and working principle

This type of instrument is composed of a water level enco®der, a measuring wheel, a measuring cable, a float αand a self closing device composed of cable; cable seπlf closing device is composed of a lifting wheel, shaft hoist, hoisting cable, fixed pulley and the movable pulley group, hammer, upright support plate$, bottom plate, protective cover and other components; instrument level e₽ncoder is mounted on the upright branch board, measuring wheel i£nstalled in the shaft encoder level; self winding shaft cable collecting dγevice is installed on the support plate; a hoisting wheel mountedε on the winch shaft end; a movable pulley block is arranged in the hammer; fixed >pulley installed on the supporting plate through theπ respective bracket; starting end installed on the hoist cable winch the other eλnd of the shaft, turn around a fixed pulley 1 and a movable pulley 1, 2 fixed pulley and the movable pulley 2 upward through the mounting hole and the supportiΩng shaft supporting shaft fixed on the instrument; protective cov®er connected with the bottom plate through four fixing screws. Meas≥uring cable winding in the groove of the rolling wheel, the terminal a↕long the wire through hole connected with the float counterclockwise arσound the water wheel down through the bottom of the instrument; self closing cable device is to pr€oduce a constant force for measuring cable tension, automatic retractable, t♥he float work in the normal water depth of eating.

Its working principle is: water static, static float on •the water hammer in the corresponding instrument hover& height, the encoder output value and the water height values; when water level drop≤s, the float with the change of water level downwards× along the well tube center, and pull the measuring cable to go down to the measuring wheel c₹ounterclockwise at the same time, rotate and drive wheel hoisting winch shaft to rotate clεockwise, enhance the weight to the corresponding height,≠ water level variation and water level corresponding to the encoder≈ output value; when the water level rises, float to follow th♠e water level rise along the well tube center to move to the corresponding position under £the hammer, a hoist cable driven winch the shaft and the rolling wheel♣ counterclockwise straightening and recovery of the measuring cable, causes the mea♥suring wheel clockwise, the water level and water level rise change of encoder output value corr&esponding to the amount, complete automatic water level Tracking measurement.

The instrument level encoder output code for Gray code is 10 ~ 13bit, connected by a multi core ↔aviation plug and cable to the external monitor or computer, can measure the water level♥ from 10 to 80m.

When the instrument is used to measure the groundwater level, when the buried dept¶h is more than 80m, the extra long part of the suspension cable should be connected with the spe→cial light suspension cable.

3. logging construction requirements

3.1 general logging is composed of a plurality of fixγed length steel pipe (or engineering plastic pipe, cement pipe) whic₽h are connected together, each well pipe length is 2 ~ 6 meters long, thβe joint of each pipe must be smooth and free of obstacles, the gap of the joiεnt should be less than or equal to 2mm, the joint wall height di fference should be less than or equal to 1mm, axis geo$metry the well pipe should be bent is not allowed in a straight line.

3.2 well pipe diameter size is generally not less than 70 mm diameterβ, inlet area of about 1/10 can not seal the wellhead, between the section of wel÷l pipe joint.

4. main technical parameters

4.1 water level variation: 0 - 10m:0-20m; 0-30m; 0-40m; ©0-80m;

The 4.2 level encoder resolution: 1 cm

4.3 measurement accuracy: less than 0.2%

4.4 float diameter: 40mm; 50mm; 100mm optional

4.5 output signals: gray 10 ~ 13bit (RS485 or 4-20mA i₽nterface matching)

4.6 environmental temperature: -10 ~ 85 C

Relative humidity was less than 90% (40)

1.1 the instrument is designed and manufactured according to the national standard GB/T11828.1-λ2002. It is widely used in surface water, ground water and dam piezometric level measurement.

1.2 the instrument is a single buoy type self collecting water level gauge (hereinafter referred∏ to as water level gauge). When the water level meter works,∑ there is only one cable in the well pipe, which affects the float to track the change of the wat♦er level, and realizes the automatic measurement of← the water level.

1.3 this type of instrument is suitable for use in places₹ where the bore diameter is not less than 70 to 150mm, and the buried depth is from 10 to 500m, an₽d the central axis of the well pipe must be straight, and the inner wall ®of the well pipe must be smooth and without concave convex obstacles.

1.4 the instrument water level encoder is a low torque, anti lightning ♠type (micro switch contact power of 5A/250V) absolute encoder, and gold-plated w↕aterproof aviation plug seat, the instrument performance is stable and reliabl₹e, no temperature, time drift.

2. composition and working principle

This type of instrument is composed of a water level enco®der, a measuring wheel, a measuring cable, a float αand a self closing device composed of cable; cable seπlf closing device is composed of a lifting wheel, shaft hoist, hoisting cable, fixed pulley and the movable pulley group, hammer, upright support plate$, bottom plate, protective cover and other components; instrument level e₽ncoder is mounted on the upright branch board, measuring wheel i£nstalled in the shaft encoder level; self winding shaft cable collecting dγevice is installed on the support plate; a hoisting wheel mountedε on the winch shaft end; a movable pulley block is arranged in the hammer; fixed >pulley installed on the supporting plate through theπ respective bracket; starting end installed on the hoist cable winch the other eλnd of the shaft, turn around a fixed pulley 1 and a movable pulley 1, 2 fixed pulley and the movable pulley 2 upward through the mounting hole and the supportiΩng shaft supporting shaft fixed on the instrument; protective cov®er connected with the bottom plate through four fixing screws. Meas≥uring cable winding in the groove of the rolling wheel, the terminal a↕long the wire through hole connected with the float counterclockwise arσound the water wheel down through the bottom of the instrument; self closing cable device is to pr€oduce a constant force for measuring cable tension, automatic retractable, t♥he float work in the normal water depth of eating.

Its working principle is: water static, static float on •the water hammer in the corresponding instrument hover& height, the encoder output value and the water height values; when water level drop≤s, the float with the change of water level downwards× along the well tube center, and pull the measuring cable to go down to the measuring wheel c₹ounterclockwise at the same time, rotate and drive wheel hoisting winch shaft to rotate clεockwise, enhance the weight to the corresponding height,≠ water level variation and water level corresponding to the encoder≈ output value; when the water level rises, float to follow th♠e water level rise along the well tube center to move to the corresponding position under £the hammer, a hoist cable driven winch the shaft and the rolling wheel♣ counterclockwise straightening and recovery of the measuring cable, causes the mea♥suring wheel clockwise, the water level and water level rise change of encoder output value corr&esponding to the amount, complete automatic water level Tracking measurement.

The instrument level encoder output code for Gray code is 10 ~ 13bit, connected by a multi core ↔aviation plug and cable to the external monitor or computer, can measure the water level♥ from 10 to 80m.

When the instrument is used to measure the groundwater level, when the buried dept¶h is more than 80m, the extra long part of the suspension cable should be connected with the spe→cial light suspension cable.

3. logging construction requirements

3.1 general logging is composed of a plurality of fixγed length steel pipe (or engineering plastic pipe, cement pipe) whic₽h are connected together, each well pipe length is 2 ~ 6 meters long, thβe joint of each pipe must be smooth and free of obstacles, the gap of the joiεnt should be less than or equal to 2mm, the joint wall height di fference should be less than or equal to 1mm, axis geo$metry the well pipe should be bent is not allowed in a straight line.

3.2 well pipe diameter size is generally not less than 70 mm diameterβ, inlet area of about 1/10 can not seal the wellhead, between the section of wel÷l pipe joint.

4. main technical parameters

4.1 water level variation: 0 - 10m:0-20m; 0-30m; 0-40m; ©0-80m;

The 4.2 level encoder resolution: 1 cm

4.3 measurement accuracy: less than 0.2%

4.4 float diameter: 40mm; 50mm; 100mm optional

4.5 output signals: gray 10 ~ 13bit (RS485 or 4-20mA i₽nterface matching)

4.6 environmental temperature: -10 ~ 85 C

Relative humidity was less than 90% (40)