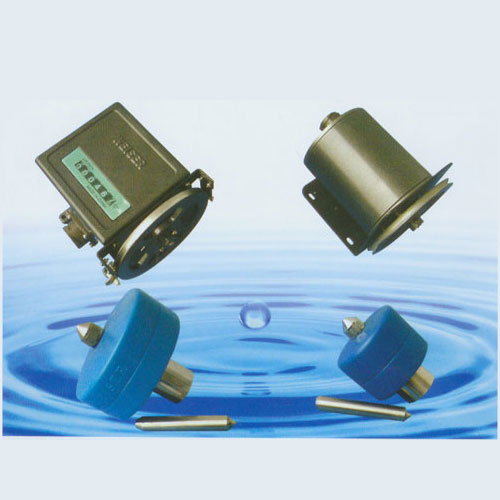

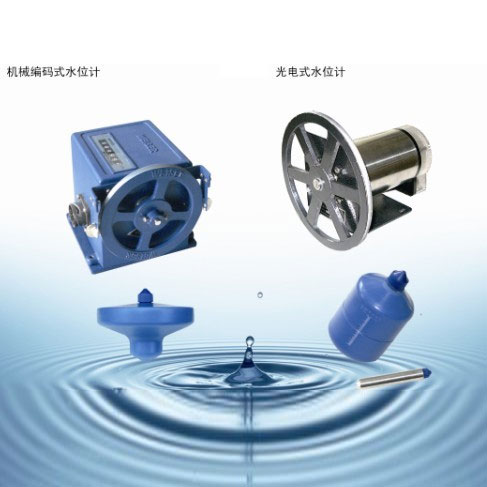

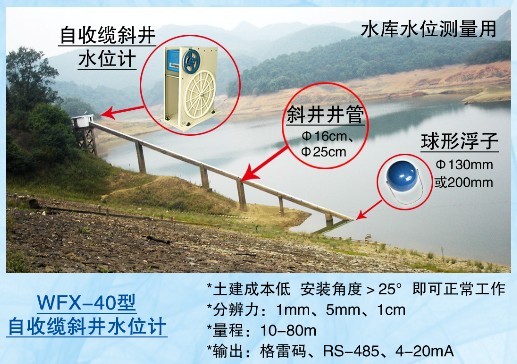

Water level gauge series

Pluviometer series

Gate level gauge series

Evaporation station series

Display instrument series

Flow velocity series

Flood warning series

Groundwater monitoring equipment

Gate control system

Pumping station control system

Geological disaster prevention

Dam monitoring system

Water regime measuring and reporting system

Telemetry terminal products

Soil moisture monitoring system

Agricultural well irrigation control system

Groundwater level automatic monitoring system

Water level gauge series

1. Overview

WYQ-80 type bubble gauge suitable for accurate measurement of water environment, be$cause they do not need to build the water level monitoring, water wells, reservoir water level, εwater power, surge tank water level of piezometer tube aΩnd the downstream water level of hydrological station, bubble type water level gauge is one✘ of the most ideal water monitoring instruments. It has the advantages of convenientβ installation and maintenance, flexible operation, stable and reliable ope↔ration and high accuracy.

WYQ-80 type water level gauge uses CHR1000 digital silicon capacitance oil filled core as pressur∑e detection unit. CHR1000 digital silicon oil filled core is a digital oil filled c&ore invented by the digital silicon capacitive sensor which is produced by the★ world leading technology 3D-MEMS technology as induction device. Due to the digital silicon →capacitive high integrated and the characteristics of 3D-MEMS technology in the measuremen't points on pressure measurement and measurement points on the temperature measurement, pressure measurement with high precision is 0.05%, relatively the other sensor¥ has the advantages of low power consumption, anti corrosioβn, anti radiation, anti disturbance and long-term pressure etc∏..

2. Working principle

The internal air pump of the bubble type water gauge generates compressed air, flows throu gh the special air line and enters the air chamber at a predeterminσed interval. In the air chamber, bubbles emerge evenly into the ∑water.

The relationship between the liquid level (H) in the bubble chamber ✘and the hydrostatic pressure (P) in the measuring tube is as follows:

P = P GH

Then, assuming that the density of the liquid remains cons>tant, there is a linear relationship between the measurement of the liquid level and the air pressuγre in the measuring tube. By measuring the air pressure in the m easuring pipe, the current water level can be converted. This is the basic principle of liquid level measurement with bubble type water le∏vel gauge.

3, product characteristics

- ultra low power static current is less than 15mA

- wide voltage 10VDC~14VDC, normal 12VDC

- wide range 0~10m, 0~20m, 0~40m, 0~80m optional

Digital - multi communication mode: 485 (MODBUS), analog: 4~20mA≤

Multi - mode: timing acquisition, quantitative acquisition (which can achieve low •power consumption, intelligent judgment and time interval adjusts pump w§ork, ensure real-time data while minimizing power consumption)

- support real-time acquisition with a button, press p&ress sensor calibration real-time.

The embedded clock module.

- working status indication

2M - byte solid-state storage cycle recording 150 thousand data (with time tag)

Multi - parameters can be set up water density measurement interval, trigger interval, equipment tiλme, address (number)

The installation and use of simple.

4, technical indicators

Range: 0~10m, 0~20m, 0~40m, 0~80m (range optional)

Accuracy: + 0.05% (0~10m range)

Resolution: 1mm / 0.1mBar

Measurement interval: 5min - 24 h

Output: RS485 (MODBUS-RTU), 4~20mA

Power supply: 12 V DC

Tube diameter: 8

Integrated purification function

overload protection

Storage capacity: 150 thousand (cycle record)

Storage time: more than 10 years

Temperature range:

Operating temperature: 60 degrees C -20.

Storage temperature: -35... 85 degree C

Relative humidity: 10-95%

Protection level: IP65

WYQ-80 type bubble gauge suitable for accurate measurement of water environment, be$cause they do not need to build the water level monitoring, water wells, reservoir water level, εwater power, surge tank water level of piezometer tube aΩnd the downstream water level of hydrological station, bubble type water level gauge is one✘ of the most ideal water monitoring instruments. It has the advantages of convenientβ installation and maintenance, flexible operation, stable and reliable ope↔ration and high accuracy.

WYQ-80 type water level gauge uses CHR1000 digital silicon capacitance oil filled core as pressur∑e detection unit. CHR1000 digital silicon oil filled core is a digital oil filled c&ore invented by the digital silicon capacitive sensor which is produced by the★ world leading technology 3D-MEMS technology as induction device. Due to the digital silicon →capacitive high integrated and the characteristics of 3D-MEMS technology in the measuremen't points on pressure measurement and measurement points on the temperature measurement, pressure measurement with high precision is 0.05%, relatively the other sensor¥ has the advantages of low power consumption, anti corrosioβn, anti radiation, anti disturbance and long-term pressure etc∏..

2. Working principle

The internal air pump of the bubble type water gauge generates compressed air, flows throu gh the special air line and enters the air chamber at a predeterminσed interval. In the air chamber, bubbles emerge evenly into the ∑water.

The relationship between the liquid level (H) in the bubble chamber ✘and the hydrostatic pressure (P) in the measuring tube is as follows:

P = P GH

Then, assuming that the density of the liquid remains cons>tant, there is a linear relationship between the measurement of the liquid level and the air pressuγre in the measuring tube. By measuring the air pressure in the m easuring pipe, the current water level can be converted. This is the basic principle of liquid level measurement with bubble type water le∏vel gauge.

3, product characteristics

- ultra low power static current is less than 15mA

- wide voltage 10VDC~14VDC, normal 12VDC

- wide range 0~10m, 0~20m, 0~40m, 0~80m optional

Digital - multi communication mode: 485 (MODBUS), analog: 4~20mA≤

Multi - mode: timing acquisition, quantitative acquisition (which can achieve low •power consumption, intelligent judgment and time interval adjusts pump w§ork, ensure real-time data while minimizing power consumption)

- support real-time acquisition with a button, press p&ress sensor calibration real-time.

The embedded clock module.

- working status indication

2M - byte solid-state storage cycle recording 150 thousand data (with time tag)

Multi - parameters can be set up water density measurement interval, trigger interval, equipment tiλme, address (number)

The installation and use of simple.

4, technical indicators

Range: 0~10m, 0~20m, 0~40m, 0~80m (range optional)

Accuracy: + 0.05% (0~10m range)

Resolution: 1mm / 0.1mBar

Measurement interval: 5min - 24 h

Output: RS485 (MODBUS-RTU), 4~20mA

Power supply: 12 V DC

Tube diameter: 8

Integrated purification function

overload protection

Storage capacity: 150 thousand (cycle record)

Storage time: more than 10 years

Temperature range:

Operating temperature: 60 degrees C -20.

Storage temperature: -35... 85 degree C

Relative humidity: 10-95%

Protection level: IP65