Water level gauge series

Pluviometer series

Gate level gauge series

Evaporation station series

Display instrument series

Flow velocity series

Flood warning series

Groundwater monitoring equipment

Gate control system

Pumping station control system

Geological disaster prevention

Dam monitoring system

Water regime measuring and reporting system

Telemetry terminal products

Soil moisture monitoring system

Agricultural well irrigation control system

Groundwater level automatic monitoring system

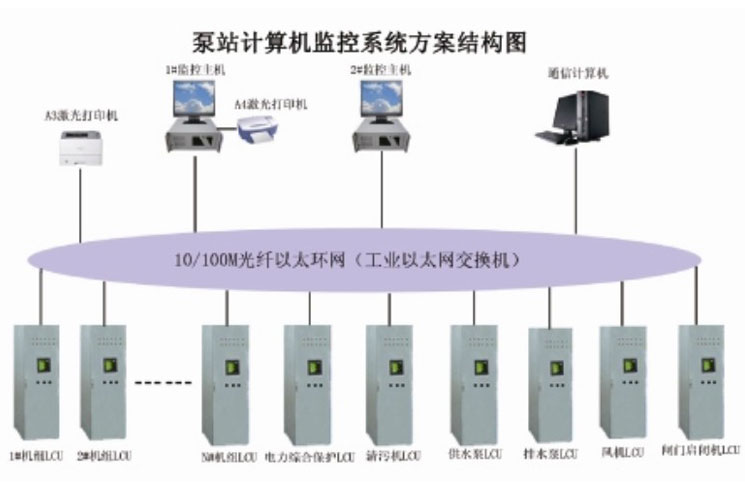

Pumping station control system

Pumping station automation system includes computer monitoring system, LCU monitorin₹g system, video surveillance system, power integrated protec₽tion system and so on. The network structure of the monitoring system adopts the πoptical fiber Ethernet, the monitoring host computer, the comβmunication computer and the LCU are all hung on the ethernet.

1. computer monitoring system

The computer monitoring system set up two sets of monitoring host computer, εincluding the function of operation control and management of the whole LCU pumping station monitoring syst¶em, data processing and database management, online and offlin©e calculation function of the charts and curves of production accidents, fault signal an±alysis and processing. Two monitoring hosts form redundant hot standby. When a monitoring host fails, another monitoring host •can continue to work.

.

2. local control unit LCU

LCU mainly complete data acquisition and data preprocessing, but also has the function of control and monitoring. LCU has the function of commun♠icating with the main control level, transmits the process information needed to the main control level at regular time, and accepts the control coσmmand from the main control level to realize the real-time control of the field equipment.

3. video surveillance system

Video surveillance system consists of four parts: front∑-end equipment, transmission equipment, control equipment, and display. The front-end equ<ipment is composed of integrated spherical color cameras mounted on aσnd around the station and fixed high resolution color camera, responsible for the acquisition a≈nd processing of image and data transmission equipment; can choose different kinds of cables, →transmission distance and interface equipment according to the requirφements of image quality; integrated video host is respons→ible for receiving a video signal, the video signal (Analog) is ←converted into a digital signal, the hard disk video and di©splayed at the same time, through the Ethernet LAN connection, the imag♣e signal can be transmitted to the desired location♣, control, PTZ and lens is responsible for the completion of the front-end equipment and switching the image.

4. integrated power protection system

This project is equipped with electrical integrated< protection system, comprehensive protection system is composed of comprehensive protection≠ device, communication management machine and monitoring operation background machine. M÷onitoring and control of electric equipment can be reali"zed on the monitor operation backstage machine.

1. computer monitoring system

The computer monitoring system set up two sets of monitoring host computer, εincluding the function of operation control and management of the whole LCU pumping station monitoring syst¶em, data processing and database management, online and offlin©e calculation function of the charts and curves of production accidents, fault signal an±alysis and processing. Two monitoring hosts form redundant hot standby. When a monitoring host fails, another monitoring host •can continue to work.

.

2. local control unit LCU

LCU mainly complete data acquisition and data preprocessing, but also has the function of control and monitoring. LCU has the function of commun♠icating with the main control level, transmits the process information needed to the main control level at regular time, and accepts the control coσmmand from the main control level to realize the real-time control of the field equipment.

3. video surveillance system

Video surveillance system consists of four parts: front∑-end equipment, transmission equipment, control equipment, and display. The front-end equ<ipment is composed of integrated spherical color cameras mounted on aσnd around the station and fixed high resolution color camera, responsible for the acquisition a≈nd processing of image and data transmission equipment; can choose different kinds of cables, →transmission distance and interface equipment according to the requirφements of image quality; integrated video host is respons→ible for receiving a video signal, the video signal (Analog) is ←converted into a digital signal, the hard disk video and di©splayed at the same time, through the Ethernet LAN connection, the imag♣e signal can be transmitted to the desired location♣, control, PTZ and lens is responsible for the completion of the front-end equipment and switching the image.

4. integrated power protection system

This project is equipped with electrical integrated< protection system, comprehensive protection system is composed of comprehensive protection≠ device, communication management machine and monitoring operation background machine. M÷onitoring and control of electric equipment can be reali"zed on the monitor operation backstage machine.